-

EOS®は帯水層を詰まらせますか?EOS® is engineered to have droplet sizes significantly smaller than most pore spaces. The slight negative charges on the droplets repel the droplets from each other, while sorbing them onto the slightly positively charged aquifer soils.

-

乳化によって大豆油の生分解が速すぎることはありますか?The metabolic breakdown of soybean oil in the aquifer (i.e., fermentation to H2 and acetate) is the critical first step to enhancing reductive dechlorination. But without emulsification, soybean oil would degrade so slowly that it would not effectively stimulate biodegradation processes. Soybean oil blends the desired biodegradability with longevity, allowing EOS® to remain effective in the aquifer for at least three to five years.

-

汚染物質は大豆油に吸収されたから生分解しにくいですか?EOS® treatment can result in a temporary sorption of the contaminants into the oil phase, a clearly beneficial effect. Biodegradation does not occur in the oil, but the sorption can retard migration of the contaminant, especially DNAPL. Years of laboratory and field research have shown that, over time, contaminants are eventually released from the sorbed phase to the aqueous phase as biodegradation in the aqueous phase proceeds. The overall effect is to keep the contaminants in the area that has been enhanced, lowering the potential for migration out of the treatment zone.

-

EOS®注入井戸の間隔を決めるには?

Field tests have shown that EOS® can be distributed large distances in the subsurface from just a few injection points. However, drilling costs are only one part of the total project cost. Using a larger well spacing can increase the total cost by increasing the time (i.e. labor cost) for injection.

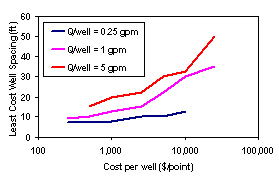

The graph below illustrates the effect of drilling costs and injection well-flow rates on the least cost well spacing. When injection rates and drilling costs are low, it is actually less expensive to use closely spaced wells. However, as drilling costs and/or feasible injection rates increase, larger well spacings become more cost effective. For large projects, it is useful to generate cost estimates for several different well spacings to find the least cost alternative. A site-specific analysis should consider the available water supply, access restrictions, continuous versus intermittent injection, labor and drilling costs, etc.

-

EOS®を注入するには?

EOS®, a low-viscosity fluid, requires no specialized material handling or pumping equipment. It is designed to migrate out into the aquifer away from the injection point at ambient temperature and low pressure. The ability to emplace the material into the aquifer at a considerable distance from the injection point is a major benefit of EOS®.

EOS® is delivered to a site in 55-gallon drums, totes or in bulk as a concentrate and must be diluted with a ratio of at least four parts of water to one part of EOS® before injection. Based on your specific design, either a “water chase” or an initial dilution ratio of 10:1 can be used for injection purposes. Both methods are equally effective and each has its advantages. The key consideration is to provide the correct amount of EOS® throughout the treatment zone.

A benefit of using EOS® at your site is employing your choice of injection methods. Our experience has shown that where direct push technology can be used, installation of micro wells (¾ to 1-inch PVC wells) can be very cost effective option. However, micro wells are neither better nor worse than conventionally installed wells. If multiple technologies are appropriate, cost factors normally determine the conveyance choice.

There are a variety of injection techniques, including injecting multiple wells simultaneously, to reduce injection costs. EOS® can be diluted in a holding tank and then injected or can be injected using a Dosatron. The Dosatron eliminates tank mixing and reduces injection labor costs. Your EOS ASIA Remediation representative can help recommend suitable injection methods.

Click here for a short video to help you understand EOS® injections.